In our last topic, I have explained how to develop your own equipment maintenance program and checklist.

As I was re -reading the Maintain Training Facilities – Competency Based Learning Material (MTF_CBLM) however, I have notice that there is a need to re-arrange some of the topics that were covered by the manual in order to easily understand what equipment maintenance is all about, its difference from the facilities maintenance and the different procedures that needs to be performed to maintain our equipment. Thus, for this particular topic I will re-arrange its presentation and focus more on tools and equipment maintenance in order to keep these respective tools and equipment in tip-top shape.

Equipment Maintenance - “...is work that is done regularly to keep equipment... in good condition and working order. “ There is a need to learn the different kinds of maintenance that can be performed on a given equipment since resources are needed in order to keep our equipment in tip-top-shape

The principal objectives of equipment maintenance can be clearly expressed as:

As I was re -reading the Maintain Training Facilities – Competency Based Learning Material (MTF_CBLM) however, I have notice that there is a need to re-arrange some of the topics that were covered by the manual in order to easily understand what equipment maintenance is all about, its difference from the facilities maintenance and the different procedures that needs to be performed to maintain our equipment. Thus, for this particular topic I will re-arrange its presentation and focus more on tools and equipment maintenance in order to keep these respective tools and equipment in tip-top shape.

Equipment Maintenance - “...is work that is done regularly to keep equipment... in good condition and working order. “ There is a need to learn the different kinds of maintenance that can be performed on a given equipment since resources are needed in order to keep our equipment in tip-top-shape

The principal objectives of equipment maintenance can be clearly expressed as:

- extension of the useful life of assets;

- ensure the optimum availability of installed equipment for protection (or service) and obtain the maximum possible return of investment;

- maintain operational readiness of equipment required for emergency use; and.

- maintain safety of personnel that utilizes these equipment.

Types of Maintenance

Planned Maintenance – are maintenance activities performed as per a given schedule as that can be based in the users / maintenance manual of a given equipment or on a set standard of the end user.

Under planed maintenance comes the following types:

Under planed maintenance comes the following types:

- Preventive Maintenance – a type of maintenance that is performed to prevent possible failures of a given equipment and to extend its useful life.

- Time-based Maintenance – is a type of maintenance that is based on a given contrition or on a predetermined time as specified in the equipment manual.

- Conditioned-based Maintenance – “visual monitoring and condition monitoring technique (temperature, hydraulic fluid wear, surface condition, crack, leaks, vibration, corrosion/erosion, electric insulation, etc.).”

- Predictive Maintenance – “Maintenance performed at a predetermined periods when the maintenance activity is most cost effective and before the equipment fails.”

- Controlled Maintenance (or Proactive Maintenance) – “maintenance performed to stabilize the reliability of machines or equipment or to condition improvement/enhancement of equipment.”

- Breakdown Maintenance (or Reactive Maintenance) – “it is maintenance performed as a reaction to failure or fails while in operation.”

- Corrective Maintenance – “Maintenance tasks initiated as a result of the observed or measured condition of an asset or system, before or after functional failure, to correct the problem. It is performed to REPAIR, RESTORE, REPLACE or CORRECT a failure.”

- Emergency – “maintenance performed to put the item on hand IMMEDIATELY to avoid serious consequences, i.e. loss of production, disrupted schedule, extensive damage to assets, idle workers or for safety reasons.”

There are lots of maintenance program that a prospective TVET Trainer needs to consider as explained by the MTF-CBLM above.

The common item that these types of maintenance needs however, are forms that can be utilized that will allow the trainer to keep tab and record all type of maintenance activities that needs to be performed or has been performed to any equipment of this equipment to keep it in shape and extend or prolong its intended service life.

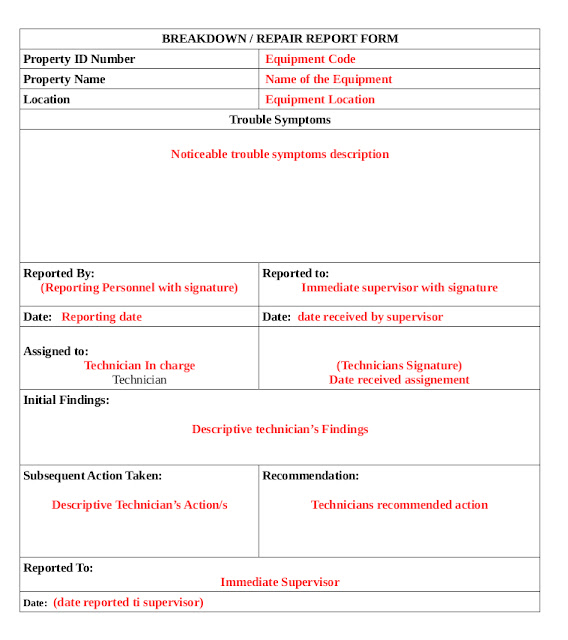

Equipment Breakdown / Repair Report Form

The equipment breakdown repair report form is one of these forms that a Trainer needs to use and keep to keep track on the repair and maintenance that was performed on a given equipment. Aside from this, this form can be used as a justification to purchase a new equipment that was declared "Beyond Economic Repair" (BER) or for the necessary purchase of parts needed to keep the equipment running and maintained throughout its service life.

|

| Figure 1. Sample Equipment Breakdown / Repair Report Form |

Figure 1 is a sample of a breakdown repair report form, there is no specific template for this form, if your institution already have a form that it utilizes for recording and reporting equipment breakdown, you can use that form as part of your portfolio requirements for MTF, provided that you ensure that the reported equipment is an equipment that your qualification uses.

For the template, you can download it below. Similar to the other templates it was made to make it self explanatory, the only thing that you need to do is fill up the needed information by following the given instructions.

For the template, you can download it below. Similar to the other templates it was made to make it self explanatory, the only thing that you need to do is fill up the needed information by following the given instructions.

The other document for MTF that you are required to submit for your portfolio is the equipment request form. Similar to the breakdown repair report, there is no specific forms for this document, you can utilize the request form that your Institution uses for this purpose, and like what I had stated above, just ensure that the requested equipment is an equipment that your qualification requires and it is properly justified.

This ends our tutorial for now, should you have any further questions, feel free to comment bellow.

Cheers!

Related post:

No comments:

Post a Comment